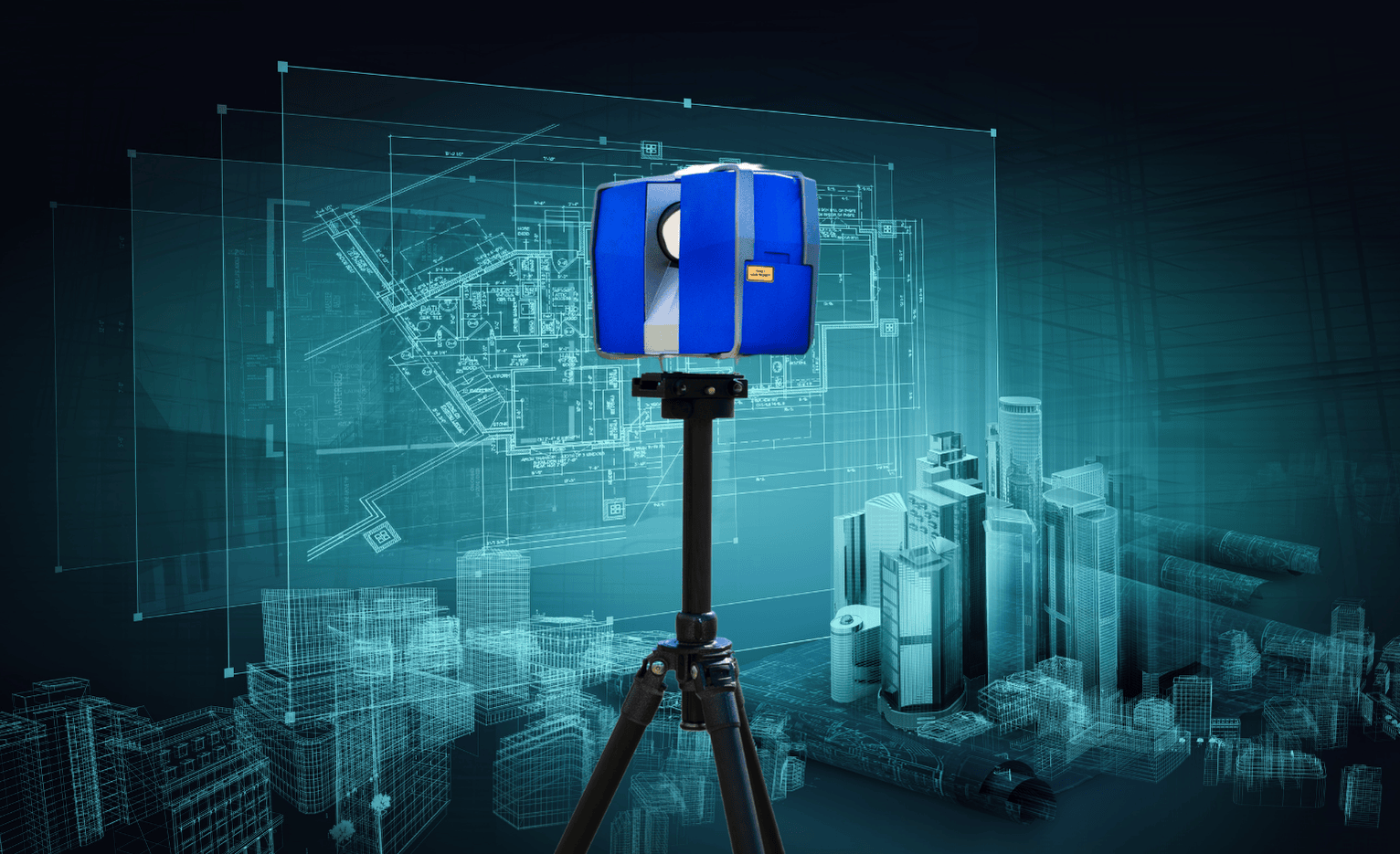

As the AEC Industry continues to advance its technological capacity and standard, one major trend we have heavily invested in is the implementation of laser scanning in the design process. If your goal is to complete your next design project quickly and efficiently, laser scanning should be an indispensable tool in your bag. As we hope to show you, any financial or psychological reluctance to use laser scanning can be assuaged once the numerous benefits of this advanced technology are better understood.

The Basics:

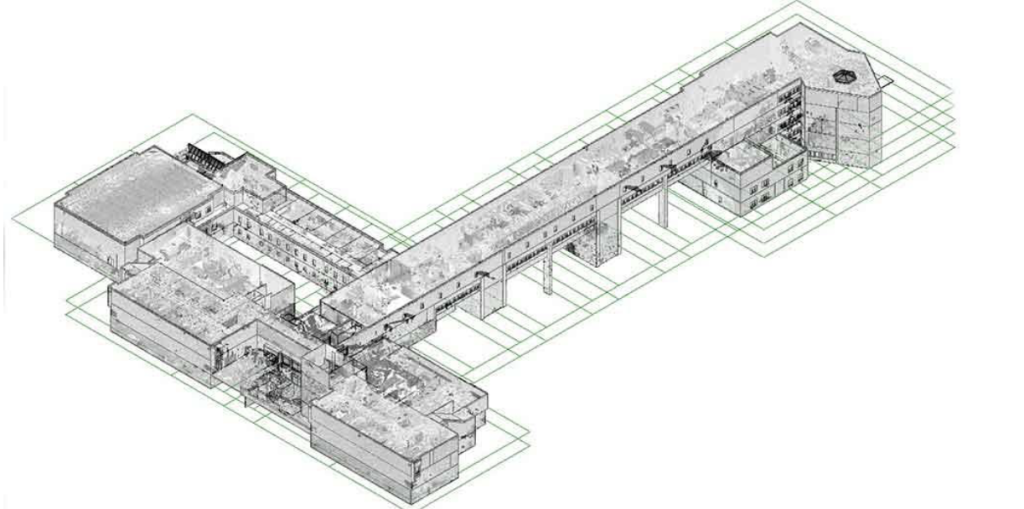

Laser scanning enables a clearer vision than traditional (albeit antiquated) techniques allow; with ultra precise scanners that create photo-realistic renderings integrated into CAD or BIM software transferred as objective data. Scanning large complex interior and exterior areas has never been easier! With our advanced laser scanners, getting a pixel-by-pixel rendering of an environment is not touted as some futuristic goal, but a reality we regularly take advantage of to assist designers. The upshot is that these scans can then be accessed by AEC professionals to plan and design layouts through processes like scan-to-BIM, but are compatible with more established softwares like CAD as well. As this practice has become more accepted in the AEC industry, the proliferation of laser scanning has resulted in precise, in-depth data for existing structures and spaces, which yields numerous advantages for designers. Ultimately, the high quality renderings save designers time and money when planning additions and renovations — This is because engineers, designers, and construction contractors can benefit from the detailed modeling renderings when planning and budgeting future plans, as well as the reduced time spent scanning and doing re-work.

Laser Scanning as a Risk Management Tool

On-Site Convenience:

Forecasting financial risks and identifying subsequent procedures to minimize their impact is key to keeping a multi-faceted project life-cycle on-track. One way laser scanning contributes to this is that it decreases the initial time to survey a site. Not only is scanning quick, but the complexity with which our scanners can record detail is unrivaled, and when done correctly eliminates the need for multiple visits or rework done when information is missed. We can also scan without having to clear a building or business because scanning can occur after dark. The combination of only needing to visit the site once and being able to scan at flexible hours ends up minimizing any inconvenience to the client that would otherwise be caused by error or inconvenient scheduling.

Accuracy Reduces Erroneous Details in As-Built Drawings:

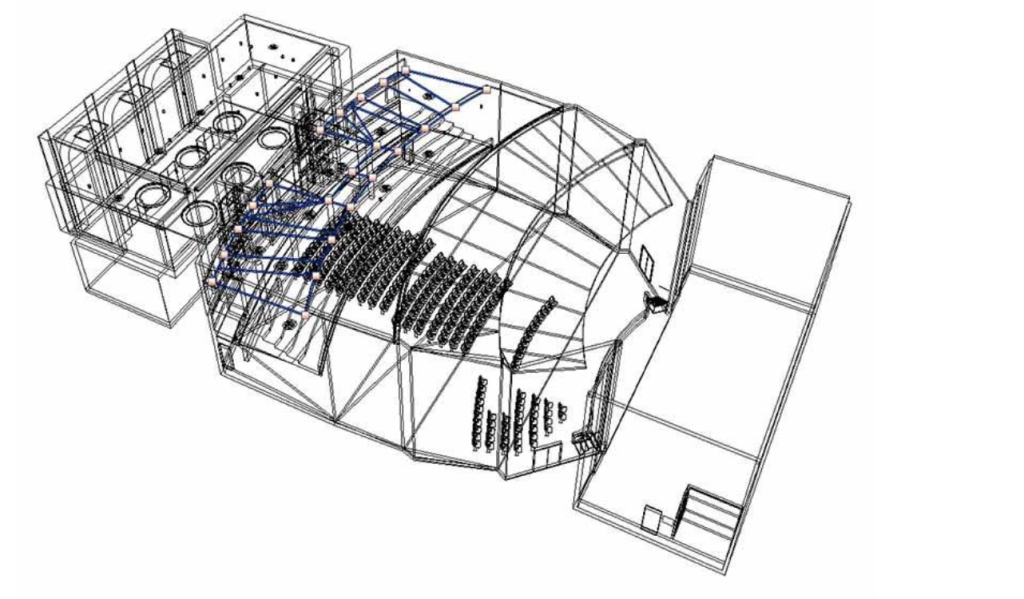

As mentioned above, the other way our scanners help mitigate risk for designers is by collecting more accurate data than can be done by hand. This increased detail and accuracy laser scanners make it easier for designers to envision and plan an area, but bringing potential inconsistencies into the light early in the design process can also reduce nagging rework and problems caused by as-built discrepancies. This results in a reduction of what’s referred to as the “accuracy gap” in models when changes in the structure occur during the construction phase: meaning that as construction occurs, changes are often made and occasionally not recorded.

At a later date, designers might run into trouble if they were looking at the initial design as it wouldn’t reflect the changes in the plans. If a designer was to go off a pre-construction plan, information on that space or building that was altered but not recorded during the construction process could cause rework. And, since keeping the project life-cycle on track is imperative in meeting customer expectations, laser scanning has become a serious risk management tool for AEC professionals and customers alike, a veritable “win-win.” The increased profitability of laser scanning technology should appease the fears of technological skeptics and excite those interested in its potential to dampen financial loss.

Better Models Means Better Design:

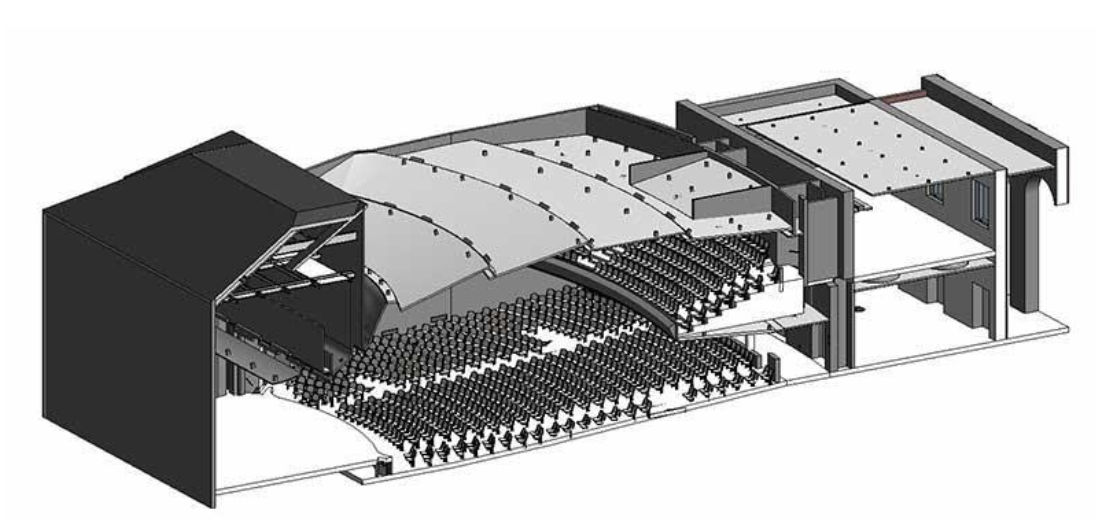

We believe having the best model, regardless of where you fall in the AEC industry, is crucial to freeing designers up to do their best work. Here are some of the ways we have assisted designers with laser scanning technology.

- Architects – Using our services: from laser scanning to modeling and drafting, has served their specific production needs throughout the design process. Projects of varying complexity (simple floor-plans or huge as-builts) are improved with more accurate documentation of as-is’.

- Interior designers – Getting a powerful production pipeline from our assistance frees them up to focus on what really matters: customers and design. More accurate and realistic models help interior designers visualize the space and create better themes and concepts while feeling confident that the documentation is precise.

- Engineers – Engineers rely on pinpoint precision when devising solutions and updates, and having the most accurate documentation of as-builts and plans is crucial to doing their best work. Cadnetics has been supporting and enabling engineers to confidently plan, invent, design and improve buildings and structures with our full-range assistance.

Check out our measurement portfolio here!

Our Expertise:

Although laser scanning can be complex and intimidating, we hope this has cleared up some of the confusion and demonstrated the various benefits of this innovative technology. At Cadnetics, we pride ourselves in being experts in the laser scanning field, with individuals specializing in all the details so you don’t have to. Combining state-of-the-art technologies and expertise to provide ancillary support on projects of any complexity, we ensure it’s done right the first time to keep your project on time!

If you are interested in how Cadnetics can help you with laser scanning, design-related tasks, or anything else in the AEC space, please reach out and we would be happy to get a conversation going with your company.