Building Information Modeling, or BIM, has many moving parts. BIM is a process and not any single phenomenon. BIM is an improvement of processes used throughout the Building Life Cycle, including communication and collaboration, which leads to better business decisions being made. BIM may include 3D laser scanning, which can take existing conditions of a structure and be shared with multiple parties working on the project. This saves the construction industry from creating errors in measurement and design flaws by creating a 3D model representation that can be shared with other parties involved in the project. This helps contractors fix problems with the design ahead of time and saves time with lower costs.

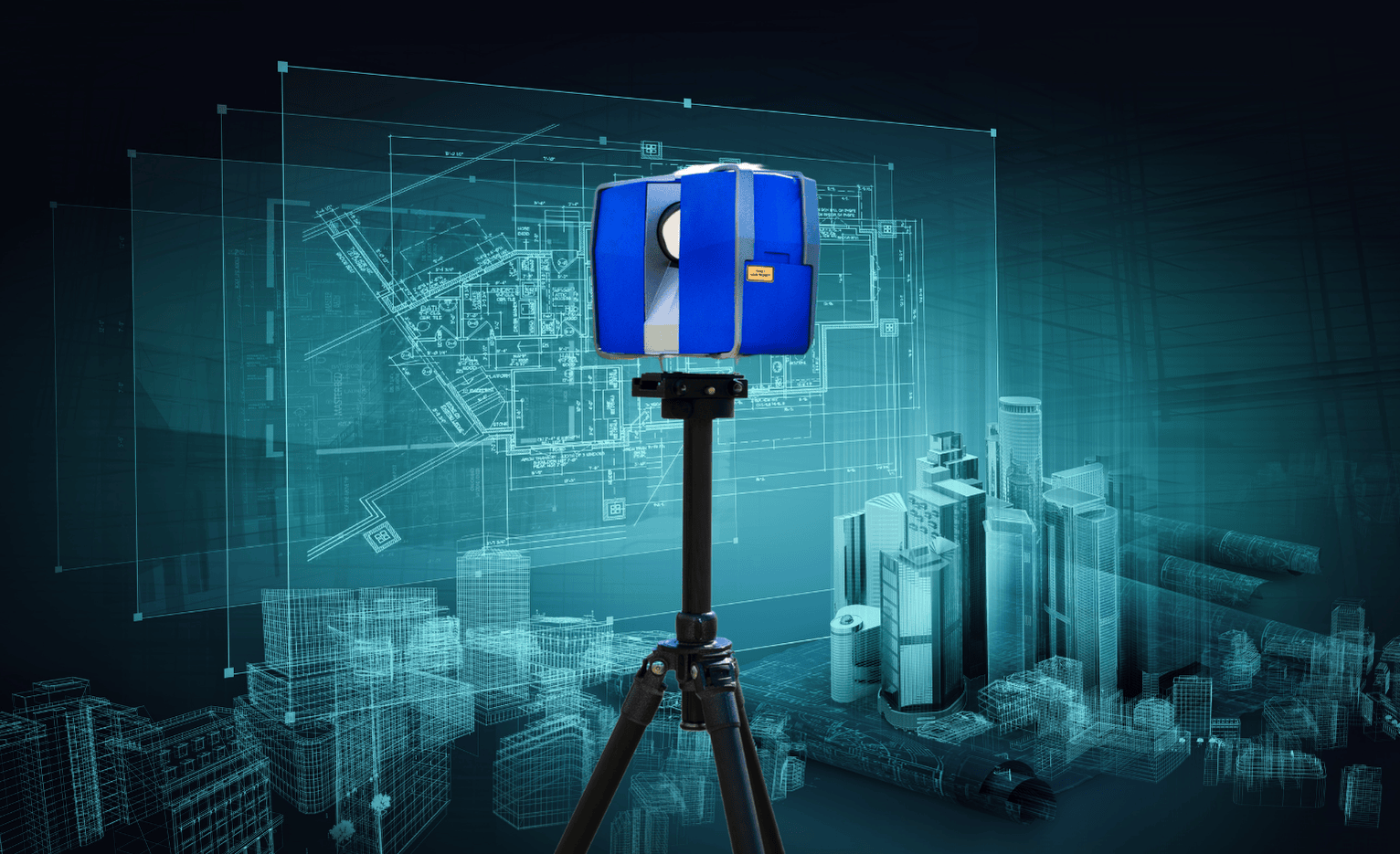

What is 3D laser scanning?

Simply put, 3D laser scanning is a process of high definition mapping, or reality capture, that uses laser scanners to instantly capture full representations of a building or structure project. This is similar to taking a panoramic photo from a full 360-degree angle, with accurate detail to every single pixel. This is often called a point cloud. The AEC has slowly been adopting 3D laser scanning and have been applying this technique to processes of Building Information Modeling. 3D laser scanning has positively impacted project processes and improved all aspects associated within the ecosystem.

3D laser scanning can be used for 3D models of existing conditions, fly-through simulations can be made, and real-time changes to remodeled designs can take place instantly. With the use of 3D laser scanners, we start to see possibilities that were not possible in the past with manual techniques. Safety can be taken into consideration first, rather than last, and documentation can be done easily. Laser scanners help lower costs and shorten scheduled deadlines, so contractors can accurately share information with other stakeholders involved with confidence. This leads to better collaboration between multiple parties and happier clients throughout the building life cycle. 3D laser scanning can benefit everyone in the AEC industry. For the rest of this article, we will be specifically talking about the benefits that can be established within the construction industry.

Here are the 8 ways 3D laser scanning can benefit contractors within the construction industry.

1. Reduce the need of rework from human error

You may be a firm who has experienced loss of capital because of poor model design. The need for rework always takes up more time than expected and can cost you more money than originally planned. With the use of 3D laser scanners, we can prevent the need of rework ahead of time, before the build. Taking the existing

conditions of a building and redesigning from that particular model within a program, such as Revit, will save you money and prevent the need of rework before physical pieces are put together. 3D laser scanning saves all valuable information of the model and manipulation of the 3D representation can be done within the program. Any measurements that you may want to gather can also be done from the 3D scan you have taken, or as others like to call it, from the complete point cloud model.

2. Scanning Documentation throughout the construction process

Not only can 3D laser scanners be used for existing conditions and pre-built projects, you may also use this scanner tool for documentation of your project throughout any point of the project life cycle. For instance, lets say you have laid out the foundation and have become framing rooms. This may be a good time to get another 3D laser scan of your project at the stage it is in. You can take this model and compare it to your design model. From there, you can see if any changes are possible, if you are on the right track, or you can have this scan be sent to stakeholders of the project. This gives the stakeholders an update they can see and can keep your team on schedule.

3. Cost and Schedule Reduction

By lowering the need for rework and having documentation of certain phases of the building, you can lower your costs while keeping an accurate, updated schedule. By knowing what materials are needed, you can see the actual costs within your 3D laser scan by adding plugins to your software. You can then change your materials to lower costs, see which materials are available, and also see the delivery time in which supplies you are waiting for. This will give you the overall picture of your project, helping you accurately plan in preparation for which building tasks can be done next. By having this information in a centralized location, everyone working on the development can be properly informed and on task at any given moment.

4. Decreased Field Time

With the use of 3D laser scanners, such as the Faro Focus 3D scanner, you can get a full representation of the project with one trip to the field. By spending a couple hours in one day to capture a complete point cloud model, you can use that model for future endeavors, such as capturing specific measurements. With tools within BIM software, using your 3D scan can be used and features on that software can measure anything captured on the scan with accuracy. This saves time from going back to the field repeatedly to measure something that wasn’t captured before. By decreasing field time and enabling fewer physical site visits, your team can focus on important business decisions to design and coordination, rather than wasting time because you did not capture a measurement.

5. Higher Precision Data

The purpose of 3D laser scanners is to capture more useful information. By having higher precision data, we are confident in the point cloud to give us everything we need to know to complete a project. 3D scanners capture every single pixel and give users in Revit or AutoCAD the ability to manipulate the existing conditions from a nonphysical representation. These scanners use precise lasers that reflect from a mirror designed to capture every point of a structure. By utilizing the technology available, we do not have to worry about human error as much as we did in the past. We can now rely on 3D laser scanners to capture all the information needed so that contractors alike can get the job done easily and efficiently.

6. Lower Overall Risk

3D laser scanners lower safety hazards that previous surveying techniques do not abide by. Hazardous areas from the field, such as unstable grounds, can be avoided with laser scanners. Technicians do not have to put themselves in danger and can capture the full representation of the structure from afar, ensuring safety first. By rotating a scanner around a structure, the point cloud can capture every pixel needed and the technician operating the laser scanner can do their job confidently. Hazardous workplaces, such as power plants, can safely be measured using 3D laser scanning techniques. If there is a chemical leak, scanners can even locate where the leak is within pipes, giving contractors a sigh of relief to send technicians out to capture scans confidently.

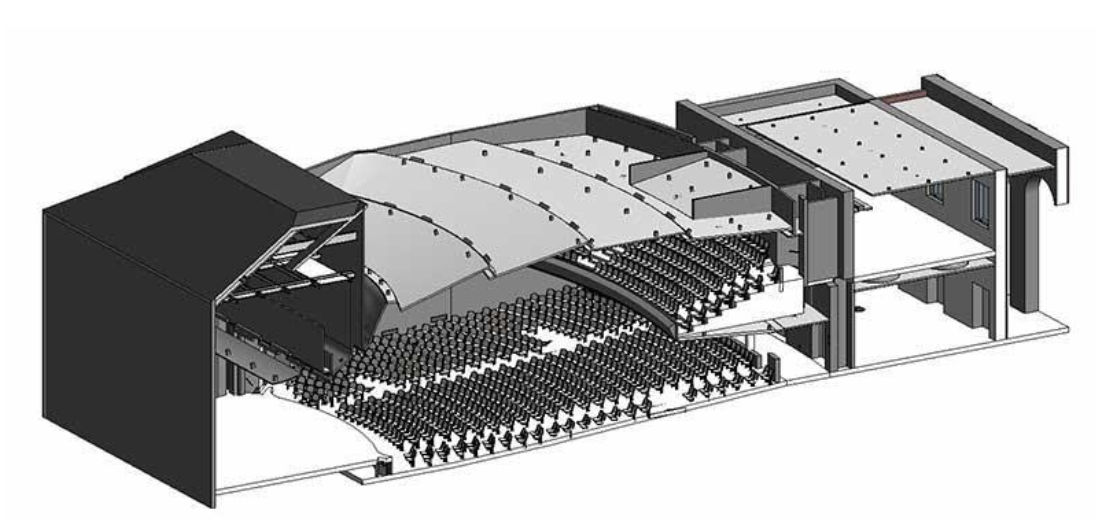

7. Capture Existing Conditions in High Resolution

As we have mentioned before, one of the most useful ways of using 3D scanners is to capture existing conditions of a building or structure. Laser scanners use powerful lasers to get high-resolution models and may stitch multiple scans together to get a point cloud. You can use your point cloud model to create a fly-through and share with stakeholders. Other parties associated with the project will be ecstatic of your highly detailed documentation and give your firm a positive outlook to build a reputation in using advanced technology for a better future in the construction industry.

8. Better Information Management During a Project

Utilizing 3D scanners during different project phases is a good way to manage new information and share it with other stakeholders. By scanning a project during midway points of specific phases, you can share your work with others, such as MEP engineers, to give them updates. By sharing your updated scans with these stakeholders, engineers will know when to expect deadlines. Investors will be satisfied with updates they can count on and show them accurate representations on their investments. Managing your project information and giving stakeholders

updates will ensure that you are doing your job with above average standards and give your team confidence to take on other projects as they come into fruition.

Conclusion

Whether you have heard of 3D laser scanning in the past or have just heard about it now, there is no doubt that contractors within the construction industry can benefit from using these laser scanners. By adopting this technology into your business processes, you can ensure a bright future for yourself and the clients you will serve. From reducing the amount of rework needed, to improved information management throughout the entire building life cycle, contractors can reap the rewards of 3D laser scanning with a click of a button.

3D laser scanners can have high upfront costs if you purchase the equipment yourself. You also have to take into consideration the costs of training on this equipment and sharing this knowledge with your staff. This is may seem like a daunting task, but it is very possible to execute. There is, however, another way to utilize 3D laser scanners.

You can find a reputable company, such as Cadnetics, to outsource your 3D laser scanning tasks. By finding a company that has over 25 years of experience using advanced technology to further the industry, you can confidently become a partner and learn about the tools as you go. This is a cheap and easy way to get involved with 3D laser scanning for first time users. We know that taking your first steps into using laser-scanning services may be tough, but we are here to help. Please send us an email for any questions or inquiries you may have. We strive ourselves to working with firms one-on-one because we know every situation is different. We want to build long-lasting relationships and partners, so contact us with your questions here! As always, we will keep giving away useful information to keep our industry well educated and alive.